VRVP Vortex Procession Flowmeter

Brief introduction:

The flowmeter integrates flow, temperature and pressure detection functions, and can automatically compensate for temperature, pressure and compression factors. It is an ideal instrument for gas metering in petroleum, chemical, electric power, metallurgy and other industries.

Features:

The instrument has no mechanical moving part. It is not easy to corrode. It is stable, reliable and has long life span. It needs no special maintenance for long-term operation.

It has high integration, small size, good performance, strong functions due to being equipped a 16-bit computer chip.

The intelligent flowmeter integrates flow probe, microprocessor, pressure and temperature sensors. It adopts built-in combination to make the structure more compact. It can directly measure the flow, pressure and temperature of the fluid, and automatically perform the compensation and compression factor correction in real time.

Double detection technology can effectively improve the detection signal strength and suppress the interference caused by pipeline vibration.

It adopts leading intelligent anti-vibration technology in China, effectively suppressing interference signals caused by vibration and pressure fluctuations.

It adopts a dot matrix display, which displays many digits, and the reading is direct and convenient. It can directly display the volume flow under working condition, the volume flow, the total amount, and the parameters such as medium pressure and temperature under standard conditions.

It adopts EEPROM technology with easy parameter setting, permanent storage, and can save up to one year of historical data.

The converter can output frequency pulse, 4~20mA analog signals, and has RS485 interface, which can be directly connected to the microcomputer, and the transmission distance can reach 1.2km.

It has multi-physical parameter alarm outputs, one of which can be selected by the user.

The meter head can be rotated 360 degrees. So, it is easy to be installed and used.

With the company's FM data collector, remote data transmission via the Internet or telephone network is available.

Pressure and temperature signals are from the integral pressure and temperature sensor respectively, which are highly interchangeable.

The whole machine has low power consumption and can be powered by an internal battery or an external power supply.

Composition and structure:

The flowmeter consists of the following seven basic components.

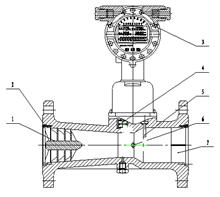

Please refer to figure 1

1. Vortex generator

It is made of aluminum alloy. It has several angled spiral blades and is

fixed at the front constricted section of the measuring tube, forcing the

fluid to produce a strong swirling flow.

2. Measuring tube

It has a flanged fluid passage of certain shape. According to

different working pressures, the measuring tube material can be

cast aluminum alloy or stainless steel.

3. Smart flow totalizer

It consists of a temperature, pressure detection analog channel, a flow detection digital channel, a micro processing unit, liquid crystal drive circuits and other auxiliary circuits, and is equipped with an external signal interface.

4. Integral temperature sensor

Pt100 platinum resistance is its temperature sensitive component. Its resistance value corresponds to temperature within a certain temperature range.

5. Pressure sensor

A piezoresistive diffusion silicon bridge is its sensitive component. Its bridge arm resistance will undergo an expected change under the action of external pressure. Therefore, under a certain excitation current, the potential difference between the two output terminals is proportional to the external pressure.

6. Piezoelectric crystal sensor

It is installed in the throat near the expansion section of the measuring tube to detect the frequency signal of the precession of the vortex.

7. Vortex eliminator

It is fixed at the outlet section of the measuring tube to eliminate vortex flow to reduce the impact on downstream instrument performance.

Working principle:

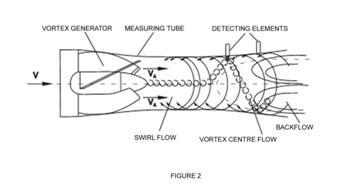

The flow sensor's (the measuring tube) flow profile is similar to that of a Venturi tube (Figure 2). A set of spiral guide vanes (vortex generator) is placed at the inlet side, and when the fluid enters the flow sensor (the measuring tube), the vortex generator forces the fluid to produce a vigorous swirl flow. When the fluid enters the diffusion section, the vortex flow is subjected to the backflow, and the second rotation starts to form a gyro-type vortex precession phenomenon. The precession frequency is proportional to the flow rate and is not affected by the physical properties and density of the fluid. The detection element measures the secondary rotation precession frequency of the fluid to obtain good linearity over a wide flow range. The signal is amplified by the preamplifier, is filtered, and is shaped into a pulse signal which is proportional to a flow rate, and then is sent to the microprocessor for integration processing together with the temperature, pressure and other detection signals, and finally the measurement result is displayed on the liquid crystal display (instantaneous flow, cumulative flow and temperature, pressure data).

Main Specification:

Specification, Basic Parameters and Performance Table

| Nominal Diameter DN(mm) | Type* | Measuring Range (m3/h) | Working Pressure (MPa) | Accuracy* | Repeatability |

| 15 | 1.0-10 | 1.6 2.5 4.0 6.3 10 16 | 1.0 1.5 | Less than 1/3 of the absolut value of the basic error limit | |

| 20 | 1.5-15 | ||||

| 25 | 3.0-30 | ||||

| 32 | 6.0~60 | ||||

| 40 | 7.0~70 | ||||

| 50 | Type A | 12~150 | |||

| Type B | 2.5~75 | ||||

| 80 | Type A | 40~400 | |||

| Type B | 10~200 | ||||

| 100 | Type A | 80~900 | |||

| Type B | 30~600 | ||||

| 150 | Type A | 150~1500 | |||

| Type B | 40~900 | ||||

| 200 | 240~3600 | 1.6;2.5;4.0 |

Note: 1. The accuracy is the system accuracy after temperature and pressure correction.

2. A, B are used to distinguish the different flow ranges via the same flow path.

Standard state conditions: P=10.325KPa, T=293.15K

Working conditions: Ambient temperature: -30℃ - +65℃

Relative humidity: 5% - 95%

Medium temperature: -20℃ - +80℃

Atmospheric pressure: 86KPa - 106KPa

Electrical specifications:

Power supply: A. External power supply: +24VDC±15%, ripple <5%, suitable for 4~20mA output, pulse output, alarm output, digital signals via RS-485, etc.

B. Integral power supply: 1 piece of 3.6V lithium battery (ER26500), there will be a lower-voltage indication when the voltage is lower than 3.0V.

Consumption: A. Less than 2W for external power supply.

B.Average power consumption is 1mW. One piece of batter can be used continuously for more than two years.

Pulse output: A. Working condition pulse signals. The flowmeter directly outputs the pulse signal of the working condition detected by the flow sensor through isolation and amplification of the optocoupler. High level ≥ 20V. While, low level ≤ 1V.

B.Calibration pulse signals. It is matched with the IC card valve controller. The high level amplitude is ≥2.8V. The low level amplitude is ≤0.2V. And the unit pulse represents the volume range which can be set from 0.001m3 to 100m3. When selecting this value, it must be noted that the frequency of the calibration pulse signal should be ≤900Hz.

C. Calibration pulse signals. The signals are output via being isolated and amplified by the optocoupler. High level ≥20V. While, low level ≤1V.

RS-485 communication (Photoelectric isolation): A. Using RS-485 interface, the instrument can be directly connected to the upper computer or secondary meter. The remote transmission shows the temperature, pressure, both standard volume flow and standard volume of the medium after temperature and pressure compensation.

B. It is matched with a HW-I data collector by RS-485 interface, which can form telephone network communication system. One data collector can carry 15 sets of the flow meters.

C. It is matched with HW-II data collector by RS-485 interface, which can form a broadband network communication system. Data is transmitted by INTERNET, and one data collector can carry 8 flow meters.

4 - 20mA standard current signals (Photoelectric isolation): It is proportional to the standard volume flow. 4mA corresponds to 0 m3/h. While, 20 mA corresponds to the maximum standard volume flow (this value can be set in the first menu). Standard: There is two-wire or three-wire system for the flowmeter, which can be recognized automatically according to the current module inserted. Correct output can be ensured.

Switch control signal output: A. Lower limit alarm signal (LP): photoelectric isolation, high and low level alarm. Alarm level can be set. Working voltage is within +12V - +24V. The maximum load current is 50mA.

B. Upper limit alarm signal (UP): photoelectric isolation, high and low level alarm. Alarm level can be set. Working voltage is within +12V - +24V. The maximum load current is 50mA.

C. Closing valve alarm output (for BC terminal, IC card controller): logic gate circuit output, normal output low level, amplitude ≤0.2V; alarm output high level, amplitude ≥2.8V, load resistance ≥100kΩ.

D. Battery undervoltage alarm output (for BL end, IC card controller): Logic gate circuit output, normal output low level, amplitude ≤0.2V; alarm output high level, amplitude ≥2.8V, load resistance ≥100kΩ.

Real-time data storage: In order to meet the needs of data management, the flowmeter has added real-time data storage function, and one of the following three could be selected by the setting.

A. Start and stop records: the most recent 1200 start and stop times, total, net flow records. Factory default item. (The corresponding communication protocol will be provided by the company separately).

B. Daily record: Dates of the last 920 days. Temperature, pressure, standard volume flow and total volume records at the zero O’clock.

C. Fixed Time interval recording: Date and time, temperature, pressure, standard volume flow and total volume records of fixed time intervals of 1200 pieces.

The above stored data can be acquired by a computer to form both a data report and a graph for analysis.

Network communication management software function:

The flow meter is matched with the data collector, and can communicate through a telephone line or a broadband network. The historical data and parameters of each flow meter in the network can be read and set. The communication management software can realize perfect management functions.

Explosion proof: Ex d IIBT4, Ex ia IICT4

Enclosure protection grade: IP65

Model Selection Table:

| Model | Code | Code Meaning | ||||

| VRVP | Vertex Procession Flow Meter | |||||

| Explosion Proof | A | Intrinsically Safe | ||||

| B | Flameproof | |||||

| Function Type | I | Common Type | ||||

| II | Intelligent Type (with Pressure and Temperature Compensation) | |||||

| Detector | D | Single Detector | ||||

| S | Dual Detector | |||||

| Signal Output | 0 | Frequency Pulse | ||||

| 1 | 4 - 20mA, tow wires | |||||

| 2 | 4 - 20mA, three wires | |||||

| 3 | RS485 Communication Interface | |||||

| Display Position | 1 | Integral Type | ||||

| 2 | Separate Type* | |||||

| Nominal Pressure | 016 | 1.6MPa | ||||

| 025 | 2.5MPa | |||||

| 040 | 4.0Mpa | |||||

| 063 | 6.3MPa | |||||

| Nominal Diameter | 025 | 25mm | ||||

| 032 | 32mm | |||||

| 040 | 40mm | |||||

| 050 | 50mm | |||||

| 080 | 80mm | |||||

| 100 | 100mm | |||||

| 150 | 150mm | |||||

| 200 | 200mm | |||||